T for thermic vent bucket.

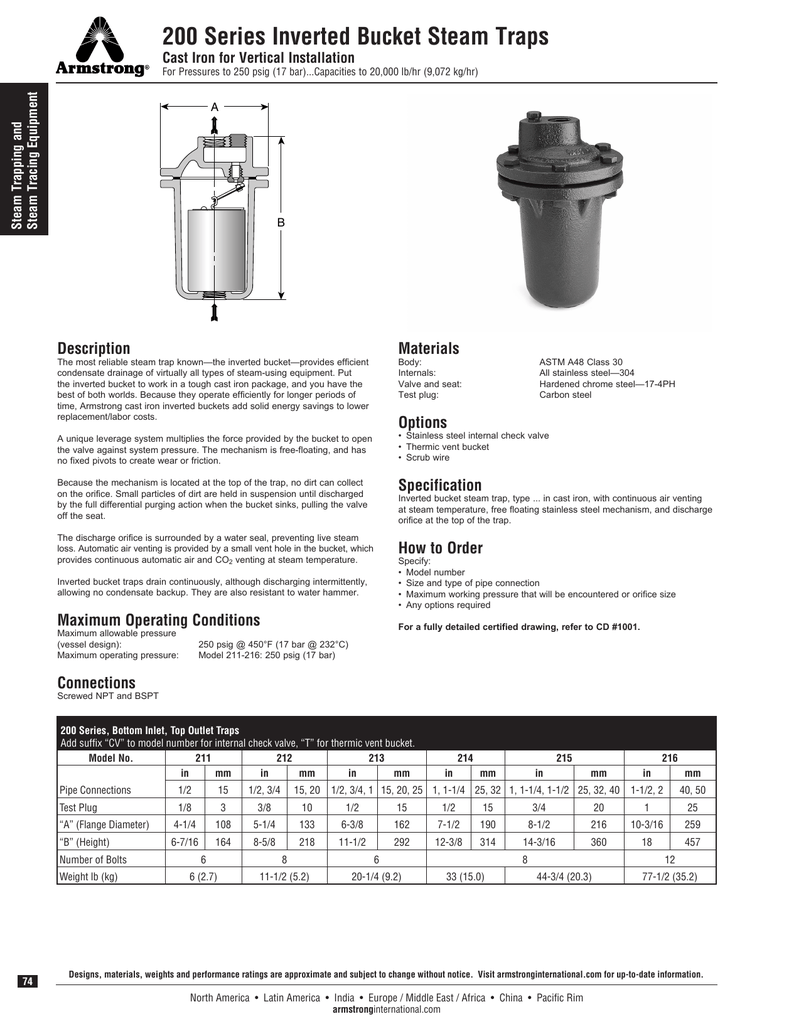

Armstrong inverted bucket steam trap 815.

The armstrong inverted bucket steam trap model 815 features a 1 1 2 pipe connection in an in line horizontal configuration and an integral strainer.

Put the inverted bucket to work in a tough cast iron package and you have the best of both worlds.

814 815 816 pipe connections 1 1 1 4 1 1 2 2 2 2 1 2 test plug 1 1 1 2 2 b height 346 413 541.

Armstrong cast iron inverted bucket traps are repairable for even bigger maintenance savings.

Because they operate efficiently for longer periods of time armstrong cast iron inverted buckets add solid energy savings to lower replacement labor costs.

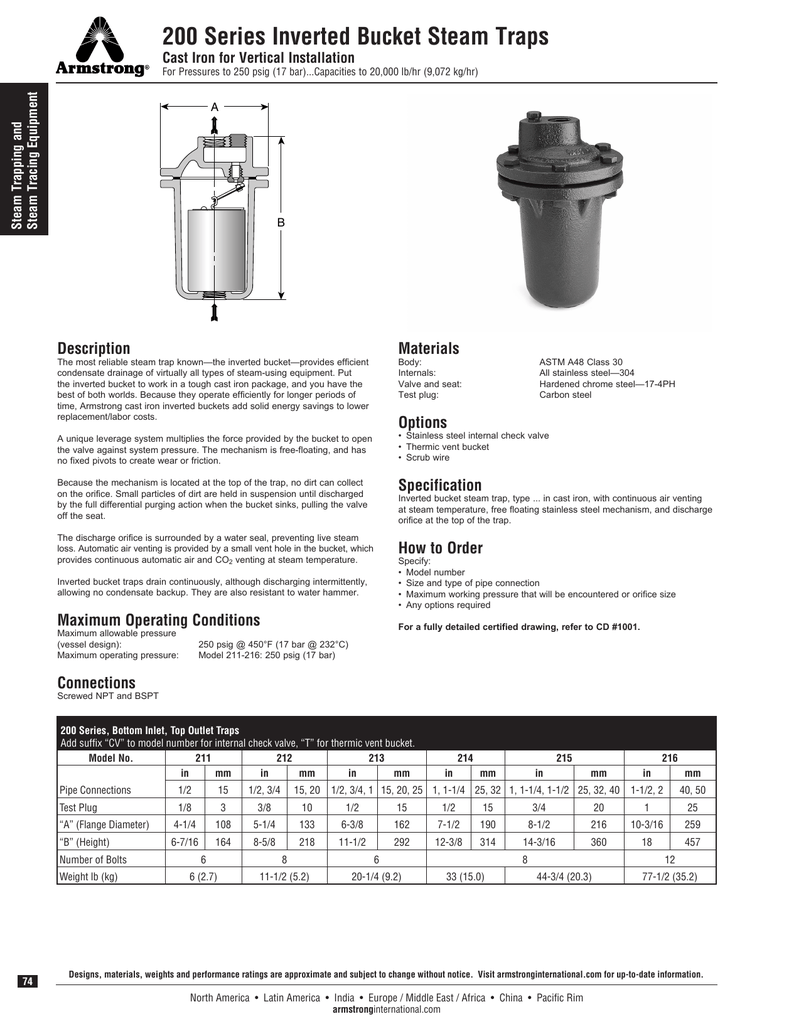

Armstrong 814 816 series inverted bucket steam traps cast iron pressures to 250 psig 17 bar capacities to 20 000 lb hr 9072 kg hr.

The most reliable steam trap known the inverted bucket provides efficient.

But as this occurs a tight seal is still preserved the ball merely seats itself more deeply.

An armstrong inverted bucket steam trap continues to operate efficiently with use.

811339 000 armstrong seal kit 1 5 8 for models 4030 4280 4360 4380 td40 with 254 326 frames.

Armstrong inverted bucket steam trap service guide armstrong series 800 813 inverted bucket steam trap submittal sheet armstrong steam trap.

Armstrongsteam and condensate group 816 maple st three rivers mi 49093 usa phone.

811339 000 armstrong seal kit 1 5 8 armstrong.

Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve.