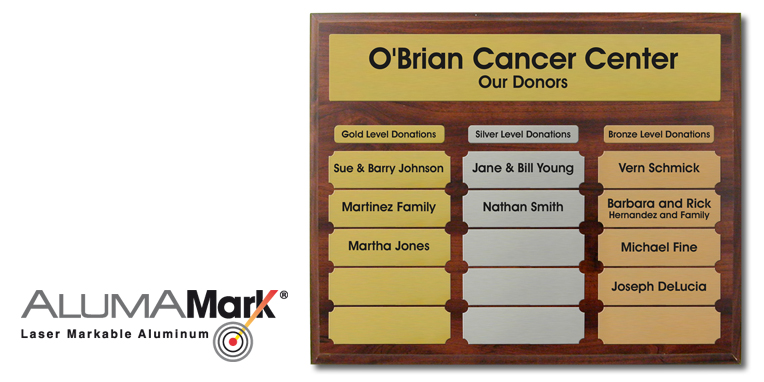

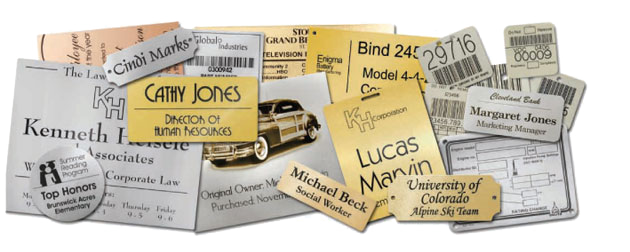

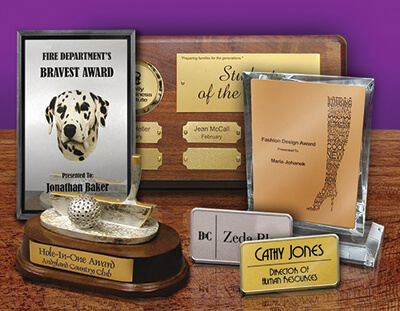

Alumamark is a specialised aluminium designed to be laser marked using lower power settings it is ideal for the production of plaques awards signs and nameplates.

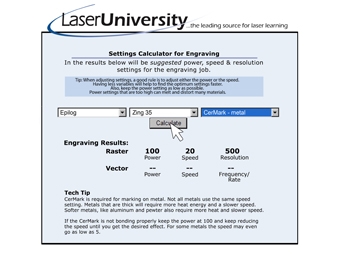

Alumamark laser settings.

In side by side tests durablack outperforms black anodized aluminum and laser markable acrylic tape in select applications.

Durablack is co2 laser markable aluminum for durable on demand marking for harsh operating environments.

191 appendix b.

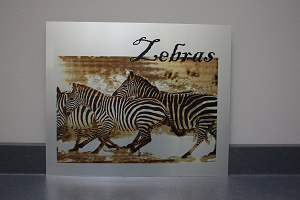

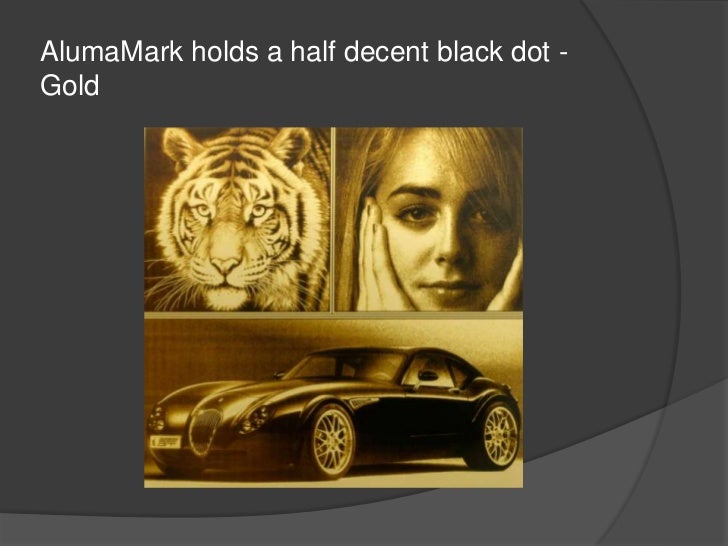

Introduced in 2001 alumamark is the only co 2 laser markable material that produces photo quality images on real metal without etching engraving or adding chemicals.

Laser processing tips for alumamark anyone who has tried to mark aluminium with a co 2 laser then you have most likely experienced the reflectivity challenge of the co 2 laser beam and metals.

Login below and you can start commenting using your own user instantly.

Unlike other laser markable products alumamark is not etched or engraved but is actually imaged by the heat of the co2 laser.

Alumamark is specialized aluminum that may be imaged or marked using a co 2 laser.

Introduction even though alumamark comes in 12 di erent nishes the settings used can be divided into two distinct groups.

It is designed so that it may be marked by using low power settings on co2 lasers.

Unique among laserable substrates alumamark allows one to create black positive marks on silver gold bronze brass or coloured backgrounds.

Marking through thermal reaction enables half tone impressions it is therefore highly.

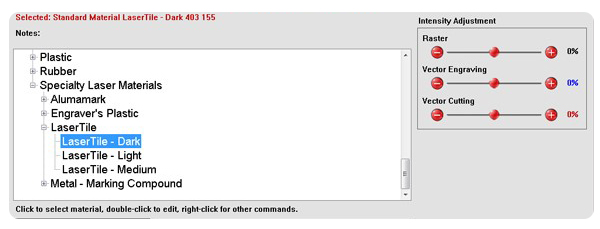

Every type of material will react differently with the laser even from one plastic to the next.

Material settings fusion series suggested material settings co2 these are only suggestions.

How to determine alumamark settings alumamark does take some to hone in on the ideal settings for a laser.

Use these settings as your starting point then adjust one variable at a time until you achieve the result you desire.

Alumamark is specialized aluminum that can be marked with any co2 laser.

Durablack is resistant to sunlight uv radiation abrasion high temperatures and chemical exposure.

No two lasers are the same so some experimentation is required to determine the ideal settings.

Unique among laserable substrates alumamark allows one to create black positive marks on silver gold bronze brass or colored backgrounds.

Using a co 2 laser you can permanently create black graphics beneath the anodised surface.