Test your material to determine laser speed and power settings.

40w laser cutting speed chart.

The following are suggested laser cutter configuration settings for various materials.

Start at 2 5 power and progress from there at 85 speed for bet results.

Different fiber optics material quality gases optical lenses cutting patterns etc will affect the cutting speed and need to be adjusted according to site conditions.

The k40 laser cutter settings i ran was at a speed of 100mm s and a power setting of 10 on the digital readout and resulted in an engraving of around 0 5mmthe janka hardness test measures the resistance of a sample of wood to denting and wear.

The following data in the laser cutting thickness speed chart is for reference only.

Settings are based on a 45w laser tube adjust accordingly for other size tubes.

Also available is a laser cutter user guide.

Laser cutter suncoo k40 laser engraver diy engraving machine for wood glass acrylic 40w co2 with air exhaust fan usb port only for windows system 12 8 inch blue this one looks to be good but it does have a 1 focal length rather than a more common 2 so it s going to be out of focus straight out of the box.

Laser cutters come in a variety of different strengths.

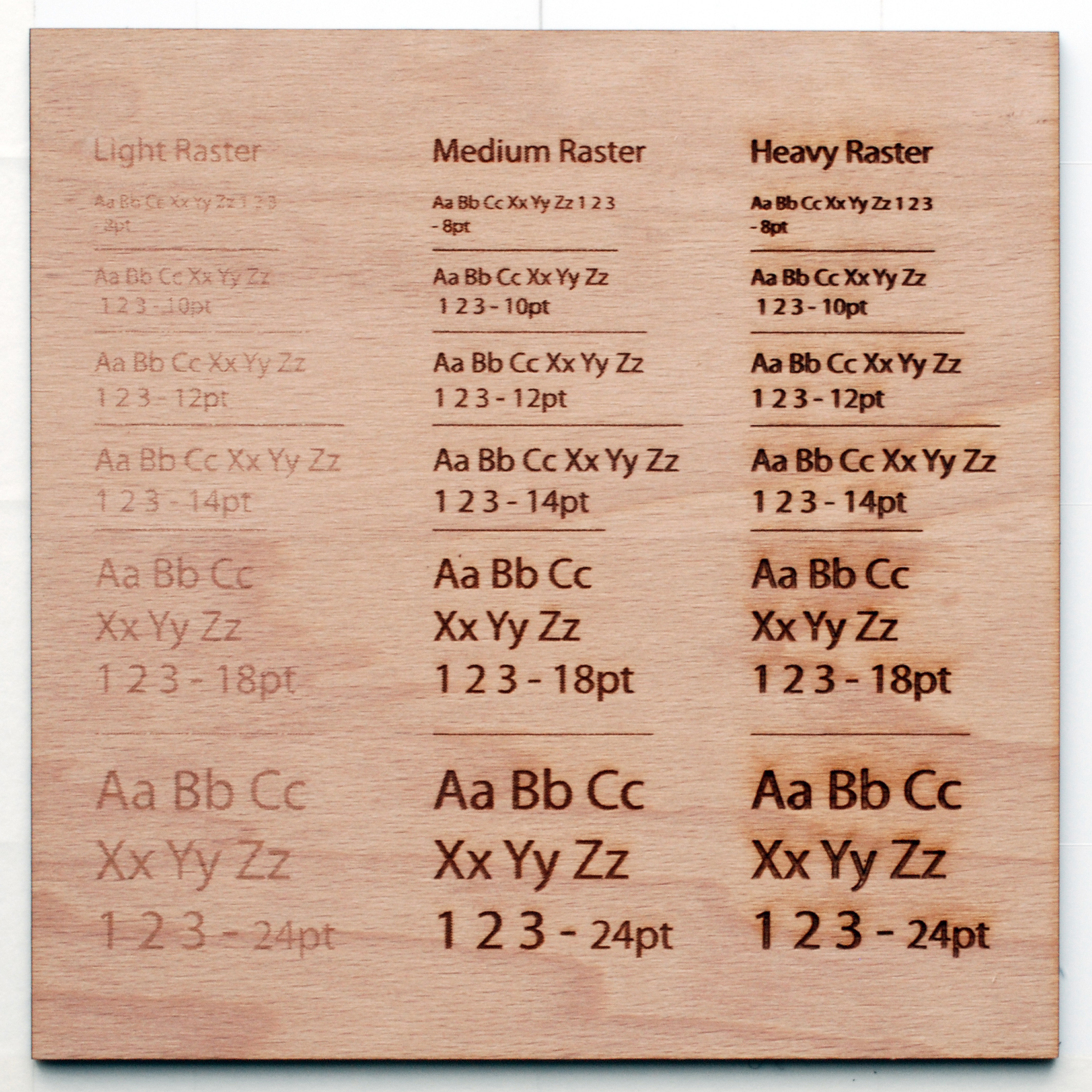

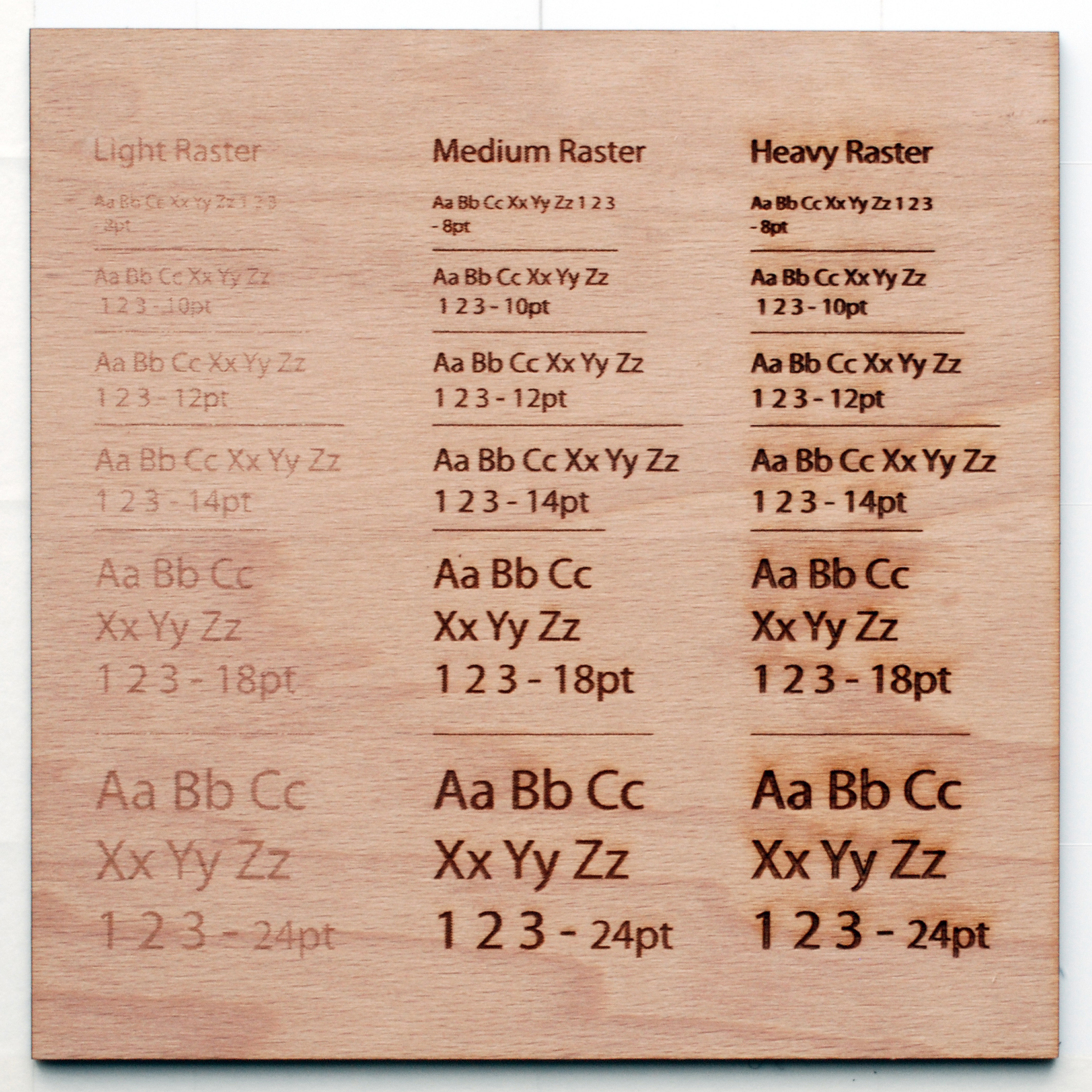

In this instructable we will use a test file to find out how the laser works with your material when it is cutting and engraving at different speed and power settings.

If you have other settings you d like to suggest please send an email to design help ncsu edu with the details.

This isn t a huge.

Chart 3 illustrates the different efficiencies for the various cutting lasers.

Recommended power settings for material test.

Material test settings based on 45w laser tube vector speeds for cutting not marking note.

We ll do this before we run our main project file so that we can optimize for the.

The final piece of the puzzle for laser processing is the cutting speed.

The differences in the operating cost are based on the maintenance and the efficiency of the style of laser being used.

5w 40w and 90w.

Many are focused on industrial use such as those used for cutting diamonds and too strong for home use.

If you re just starting out these values should provide you a good starting point to experiment from and see what works best for you.

There are three strengths that are ideal for small businesses or hobbyists.